AI-Assisted CR/DR for Nondestructive Testing

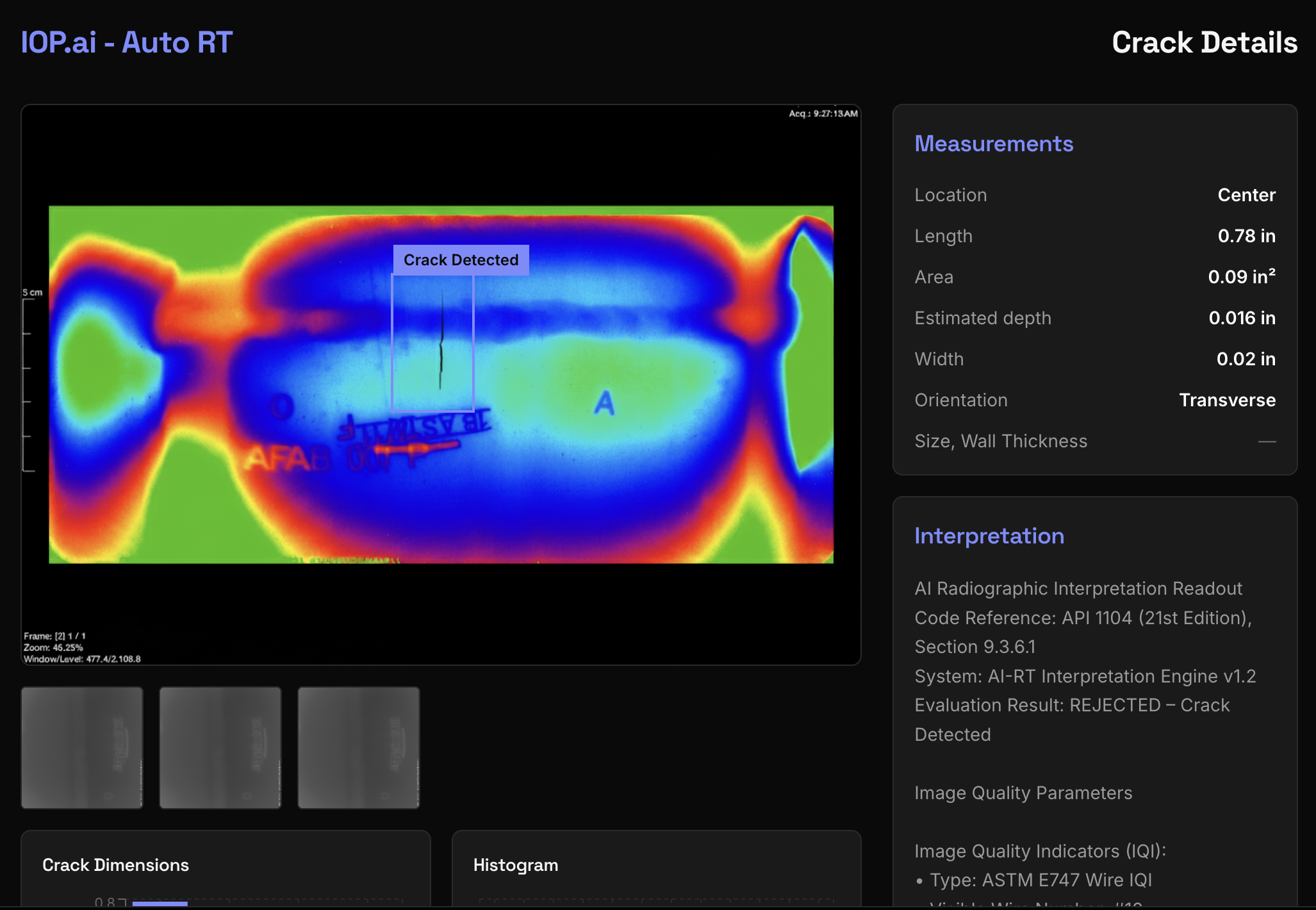

Automated defect qualification, detection, precise characterization, and code-based interpretation, powered by advanced machine learning.

Enhance confidence in your Radiographic Testing (RT) workflow with our AI-driven Automated Digital Radiography (ADR) platform.

Production-Ready ADR

Engineered for reliability, precision, and seamless integration into your existing NDT workflow. Each CR and DR image is analyzed through artificial intelligence models that replicate the precision and judgment of experienced radiographers, automating image quality verification, flaw detection, and standards-based evaluation.

High-recall detection

Ensembles tuned for small and low-contrast indications on high-resolution CR/DR.

Pixel-accurate sizing

nnU-Net refinement delivers reliable length and area for acceptance decisions.

Rules-based interpretation

Machine-readable procedures yield consistent dispositions with clause references.

Calibrated confidence

Temperature-scaled probabilities and conformal "indeterminate" routing.

Human-in-the-loop

Level III tools for quick corrections, audit trails, and continuous learning.

Production-ready

Fast inference, versioned models and rules, and a clean review workflow.

Security & Compliance

Built for regulated environments with full traceability, audit trails, and POD-based validation.

A built-in AI quality assurance engine performs automated statistical audits of completed radiographs, configurable by volume, frequency, or project scope, providing real-time quality validation, performance insights, and continuous improvement across the inspection program.

Traceable by design

Versioned models, rules, and image hashes; reproducible runs.

Audit-ready

Immutable logs, change control, and gold-set non-regression tests.

POD focus

Size-based POD curves and 90/95 reporting for critical defects.

Frequently Asked Questions

Common questions about our ADR system, implementation, and Level III collaboration.

No. It accelerates pre-read and provides explainable evidence. A Level III remains the authority for final interpretation.

Yes. Procedures are encoded as versioned rules. You can trace every disposition back to the exact clause.

We calibrate operating points, surface uncertainty, and route "indeterminate" cases for review. Active learning continually reduces false calls.

An anomaly lane flags patterns outside training distribution so reviewers can triage and label them for the next cycle.

A focused pilot typically runs 2–4 weeks once scope, data access, and acceptance thresholds are defined.

A scoped part family, representative CR/DR, acceptance criteria, and a Level III reviewer for short daily feedback.

Start a pilot on your parts

- Scope a focused family and procedure

- Establish gold-set and acceptance thresholds

- Run a 2–4 week pilot with Level III oversight